Angular Contact Ball Bearing 7000C

Strong load-bearing capacity

High rigidity

High precision

High speed

High temperature resistance

Corrosion resistance

Product Introduction

The structure of angular contact ball bearing 7000c is relatively simple, mainly composed of inner ring, outer ring, steel ball, and retainer.

The parameters of angular contact ball bearing 7000c mainly include inner diameter, outer diameter, width, contact angle, rated load, and limited speed.

Inner diameter: 10mm Outer diameter: 26mm Thickness: 8mm

There are several types of angular contact ball bearings: 7000C type (Å=15 °), 7000AC type (Å=25 °), and 7000B type (Å=40 °).

On below are 7000C series:

| Bearing No. | Boundary Dimensions | Basic Load | Limiting Speed | ||||||

| d/mm | D/mm | B | 2B | r/min | Cr/KN | Cor/KN | Greass/rpm | Oil/rpm | |

| 7000C | 10 | 26 | 8 | 16 | 0.3 | 4.9 | 2.2 | 43000 | 58000 |

| 7200C | 30 | 9 | 18 | 0.6 | 5.4 | 2.64 | 41000 | 55000 | |

| 7001C | 12 | 28 | 8 | 16 | 0.3 | 5.4 | 2.64 | 39000 | 52000 |

| 7201C | 32 | 10 | 20 | 0.6 | 7.1 | 3.45 | 36000 | 49000 | |

| 7002C | 15 | 32 | 9 | 18 | 0.3 | 6.25 | 3.4 | 34000 | 45000 |

| 7202C | 35 | 11 | 22 | 0.6 | 9 | 4.5 | 32000 | 42000 | |

| 7302C | 42 | 13 | 26 | 1 | 13.3 | 6.85 | 28000 | 38000 | |

| 7003C | 17 | 35 | 10 | 20 | 0.3 | 7.7 | 4.1 | 31000 | 41000 |

| 7203C | 40 | 12 | 24 | 0.6 | 11.2 | 5.75 | 29000 | 38000 | |

| 7303C | 47 | 14 | 28 | 1 | 15.7 | 8.25 | 26000 | 35000 | |

| 7004C | 20 | 42 | 12 | 24 | 0.6 | 1.5 | 6.05 | 27000 | 36000 |

| 7204C | 47 | 14 | 28 | 1 | 14.6 | 8.15 | 25000 | 34000 | |

| 7304C | 52 | 15 | 30 | 1.1 | 18.5 | 9.95 | 23000 | 31000 | |

| 7805C | 25 | 37 | 7 | 14 | 0.3 | 5.05 | 3.85 | 27000 | 36000 |

| 7905C | 42 | 9 | 18 | 0.3 | 7.85 | 5.4 | 25000 | 33000 | |

| 7005C | 47 | 12 | 24 | 0.6 | 11.7 | 7.45 | 23000 | 31000 | |

| 7205C | 52 | 15 | 30 | 1 | 16.6 | 10.2 | 21000 | 28000 | |

| 7305C | 62 | 17 | 34 | 1.1 | 26.4 | 15.3 | 19000 | 26000 | |

| 7806C | 30 | 42 | 7 | 14 | 0.3 | 5.35 | 4.5 | 23000 | 31000 |

| 7906C | 47 | 9 | 18 | 0.3 | 8.3 | 6.25 | 21000 | 28000 | |

| 7006C | 55 | 13 | 26 | 1 | 15.1 | 10.3 | 20000 | 26000 | |

| 7206C | 62 | 16 | 32 | 1 | 23 | 14.7 | 18000 | 24000 | |

| 7306C | 72 | 19 | 38 | 1.1 | 32.5 | 20.3 | 16000 | 22000 | |

| 7807C | 35 | 47 | 7 | 14 | 0.3 | 5.8 | 5.25 | 20000 | 27000 |

| 7907C | 55 | 10 | 20 | 0.6 | 13.2 | 9.65 | 19000 | 25000 | |

| 7007C | 62 | 14 | 28 | 1 | 19.1 | 13.7 | 17000 | 23000 | |

| 7207C | 72 | 17 | 34 | 1.1 | 30.5 | 19.9 | 16000 | 21000 | |

| 7307C | 80 | 21 | 42 | 1.5 | 40.5 | 25.8 | 14000 | 19000 | |

| 7808C | 40 | 52 | 7 | 14 | 0.3 | 6.05 | 5.75 | 18000 | 24000 |

| 7908C | 62 | 12 | 24 | 0.6 | 14 | 11.1 | 17000 | 22000 | |

| 7008C | 68 | 15 | 30 | 1 | 20.6 | 15.9 | 15000 | 21000 | |

| 7208C | 80 | 18 | 36 | 1.1 | 36.5 | 25.2 | 14000 | 19000 | |

| 7308C | 90 | 23 | 46 | 1.5 | 49.5 | 32.5 | 13000 | 17000 | |

| 7809C | 45 | 58 | 7 | 14 | 0.3 | 7.6 | 7.4 | 16000 | 21000 |

| 7909C | 68 | 12 | 24 | 0.6 | 17.3 | 14.1 | 15000 | 20000 | |

| 7009C | 75 | 16 | 32 | 1 | 24.4 | 19.3 | 14000 | 19000 | |

| 7209C | 85 | 19 | 38 | 1.1 | 41 | 28.8 | 13000 | 17000 | |

| 7309C | 100 | 25 | 50 | 1.5 | 64 | 43 | 11000 | 15000 | |

| 7810C | 50 | 65 | 7 | 14 | 0.3 | 7.9 | 8.05 | 14000 | 19000 |

| 7910C | 72 | 12 | 24 | 0.6 | 18.3 | 15.8 | 14000 | 18000 | |

| 7010C | 80 | 16 | 32 | 1 | 26 | 21.9 | 13000 | 17000 | |

| 7210C | 90 | 20 | 40 | 1.1 | 43 | 31.5 | 12000 | 15000 | |

| 7310C | 110 | 27 | 54 | 2 | 75 | 51.5 | 10000 | 14000 | |

| 7811C | 55 | 72 | 9 | 18 | 0.3 | 13.1 | 12.7 | 13000 | 18000 |

| 7911C | 80 | 13 | 26 | 1 | 19.1 | 17.7 | 12000 | 16000 | |

| 7011C | 90 | 18 | 36 | 1.1 | 34 | 28.6 | 12000 | 15000 | |

| 7211C | 100 | 21 | 42 | 1.5 | 53 | 40 | 11000 | 14000 | |

| 7311C | 120 | 29 | 58 | 2 | 87 | 60.5 | 9400 | 13000 | |

| 7812C | 60 | 78 | 10 | 20 | 0.3 | 13.4 | 13.5 | 12000 | 16000 |

| 7912C | 85 | 13 | 26 | 1 | 20 | 19.5 | 11000 | 15000 | |

| 7012C | 95 | 18 | 36 | 1.1 | 35 | 30.5 | 11000 | 14000 | |

| 7212C | 110 | 22 | 44 | 1.5 | 64 | 49.5 | 9700 | 13000 | |

| 7312C | 130 | 31 | 62 | 2.1 | 99 | 70.5 | 8700 | 12000 | |

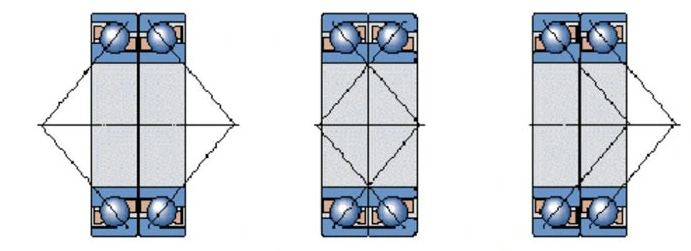

There are three installation methods for angular contact ball bearings: back-to-back (O-shaped configuration), face-to-face (X-shaped configuration), and series arrangement (T-shaped configuration).

Application Area

Angular Contact Ball Bearing 7000C has a wide range of applications, mainly used in corrugated pipe equipment, hardness testers, cement machinery, tire excavators, bakery equipment, lathes, filling machinery, flat plates, flattening machines, explosion-proof pumps, pharmaceutical mixing equipment, cooling towers, drop shot machines, punching machines, flame arresters, engraving machines, aluminum welding machines, knitting machinery, plastic granulators, pre sewing equipment, insertion machines, surgical equipment, die-cutting machines, automatic welding machines, laser cutting machines, cross cutting machines, molds, sterilization machines, ball mills, Glue dispensing equipment, etc,

If you interested in Angular Contact Ball Bearing 7000C,and others.Plese send your requirements to us.

| Bearing No. | Boundary Dimensions | Basic Load | Limiting Speed | ||||||

| d/mm | D/mm | B | 2B | r/min | Cr/KN | Cor/KN | Greass/rpm | Oil/rpm | |

| 7000C | 10 | 26 | 8 | 16 | 0.3 | 4.9 | 2.2 | 43000 | 58000 |

| 7200C | 30 | 9 | 18 | 0.6 | 5.4 | 2.64 | 41000 | 55000 | |

| 7001C | 12 | 28 | 8 | 16 | 0.3 | 5.4 | 2.64 | 39000 | 52000 |

| 7201C | 32 | 10 | 20 | 0.6 | 7.1 | 3.45 | 36000 | 49000 | |

| 7002C | 15 | 32 | 9 | 18 | 0.3 | 6.25 | 3.4 | 34000 | 45000 |

| 7202C | 35 | 11 | 22 | 0.6 | 9 | 4.5 | 32000 | 42000 | |

| 7302C | 42 | 13 | 26 | 1 | 13.3 | 6.85 | 28000 | 38000 | |

| 7003C | 17 | 35 | 10 | 20 | 0.3 | 7.7 | 4.1 | 31000 | 41000 |

| 7203C | 40 | 12 | 24 | 0.6 | 11.2 | 5.75 | 29000 | 38000 | |

| 7303C | 47 | 14 | 28 | 1 | 15.7 | 8.25 | 26000 | 35000 | |

| 7004C | 20 | 42 | 12 | 24 | 0.6 | 1.5 | 6.05 | 27000 | 36000 |

| 7204C | 47 | 14 | 28 | 1 | 14.6 | 8.15 | 25000 | 34000 | |

| 7304C | 52 | 15 | 30 | 1.1 | 18.5 | 9.95 | 23000 | 31000 | |

| 7805C | 25 | 37 | 7 | 14 | 0.3 | 5.05 | 3.85 | 27000 | 36000 |

| 7905C | 42 | 9 | 18 | 0.3 | 7.85 | 5.4 | 25000 | 33000 | |

| 7005C | 47 | 12 | 24 | 0.6 | 11.7 | 7.45 | 23000 | 31000 | |

| 7205C | 52 | 15 | 30 | 1 | 16.6 | 10.2 | 21000 | 28000 | |

| 7305C | 62 | 17 | 34 | 1.1 | 26.4 | 15.3 | 19000 | 26000 | |

| 7806C | 30 | 42 | 7 | 14 | 0.3 | 5.35 | 4.5 | 23000 | 31000 |

| 7906C | 47 | 9 | 18 | 0.3 | 8.3 | 6.25 | 21000 | 28000 | |

| 7006C | 55 | 13 | 26 | 1 | 15.1 | 10.3 | 20000 | 26000 | |

| 7206C | 62 | 16 | 32 | 1 | 23 | 14.7 | 18000 | 24000 | |

| 7306C | 72 | 19 | 38 | 1.1 | 32.5 | 20.3 | 16000 | 22000 | |

| 7807C | 35 | 47 | 7 | 14 | 0.3 | 5.8 | 5.25 | 20000 | 27000 |

| 7907C | 55 | 10 | 20 | 0.6 | 13.2 | 9.65 | 19000 | 25000 | |

| 7007C | 62 | 14 | 28 | 1 | 19.1 | 13.7 | 17000 | 23000 | |

| 7207C | 72 | 17 | 34 | 1.1 | 30.5 | 19.9 | 16000 | 21000 | |

| 7307C | 80 | 21 | 42 | 1.5 | 40.5 | 25.8 | 14000 | 19000 | |

| 7808C | 40 | 52 | 7 | 14 | 0.3 | 6.05 | 5.75 | 18000 | 24000 |

| 7908C | 62 | 12 | 24 | 0.6 | 14 | 11.1 | 17000 | 22000 | |

| 7008C | 68 | 15 | 30 | 1 | 20.6 | 15.9 | 15000 | 21000 | |

| 7208C | 80 | 18 | 36 | 1.1 | 36.5 | 25.2 | 14000 | 19000 | |

| 7308C | 90 | 23 | 46 | 1.5 | 49.5 | 32.5 | 13000 | 17000 | |

| 7809C | 45 | 58 | 7 | 14 | 0.3 | 7.6 | 7.4 | 16000 | 21000 |

| 7909C | 68 | 12 | 24 | 0.6 | 17.3 | 14.1 | 15000 | 20000 | |

| 7009C | 75 | 16 | 32 | 1 | 24.4 | 19.3 | 14000 | 19000 | |

| 7209C | 85 | 19 | 38 | 1.1 | 41 | 28.8 | 13000 | 17000 | |

| 7309C | 100 | 25 | 50 | 1.5 | 64 | 43 | 11000 | 15000 | |

| 7810C | 50 | 65 | 7 | 14 | 0.3 | 7.9 | 8.05 | 14000 | 19000 |

| 7910C | 72 | 12 | 24 | 0.6 | 18.3 | 15.8 | 14000 | 18000 | |

| 7010C | 80 | 16 | 32 | 1 | 26 | 21.9 | 13000 | 17000 | |

| 7210C | 90 | 20 | 40 | 1.1 | 43 | 31.5 | 12000 | 15000 | |

| 7310C | 110 | 27 | 54 | 2 | 75 | 51.5 | 10000 | 14000 | |

| 7811C | 55 | 72 | 9 | 18 | 0.3 | 13.1 | 12.7 | 13000 | 18000 |

| 7911C | 80 | 13 | 26 | 1 | 19.1 | 17.7 | 12000 | 16000 | |

| 7011C | 90 | 18 | 36 | 1.1 | 34 | 28.6 | 12000 | 15000 | |

| 7211C | 100 | 21 | 42 | 1.5 | 53 | 40 | 11000 | 14000 | |

| 7311C | 120 | 29 | 58 | 2 | 87 | 60.5 | 9400 | 13000 | |

| 7812C | 60 | 78 | 10 | 20 | 0.3 | 13.4 | 13.5 | 12000 | 16000 |

| 7912C | 85 | 13 | 26 | 1 | 20 | 19.5 | 11000 | 15000 | |

| 7012C | 95 | 18 | 36 | 1.1 | 35 | 30.5 | 11000 | 14000 | |

| 7212C | 110 | 22 | 44 | 1.5 | 64 | 49.5 | 9700 | 13000 | |

| 7312C | 130 | 31 | 62 | 2.1 | 99 | 70.5 | 8700 | 12000 | |