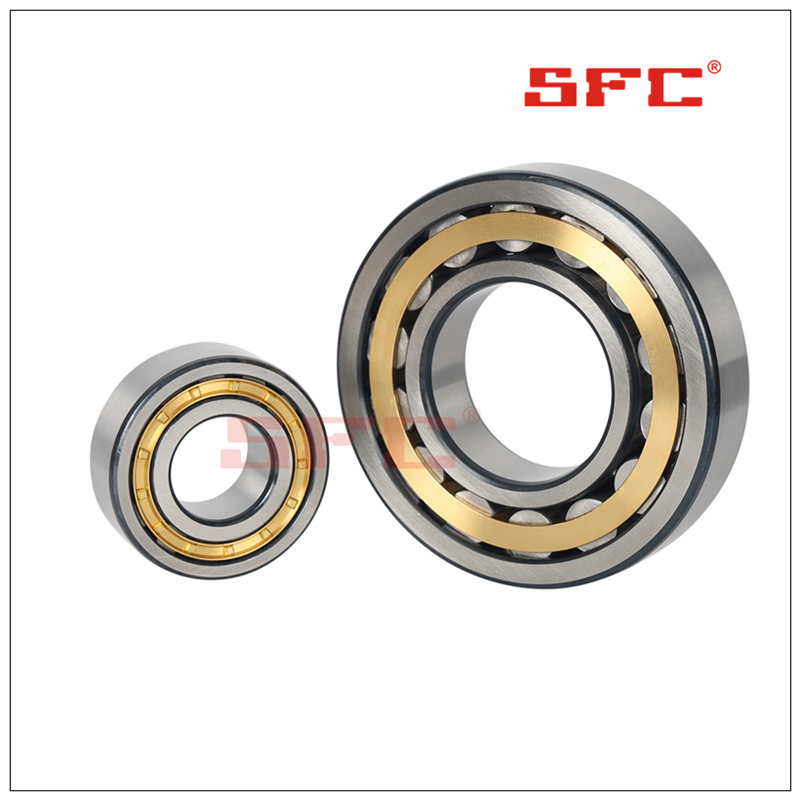

NU202EC NJ202ECP Hot Sale Single Row Sylindrical Roller Bearing

High radial bearing capacity

high speed

Low friction

Easy to maintain

Separable

Impact resistance

P0,P5,P6,P4

Product Introduction

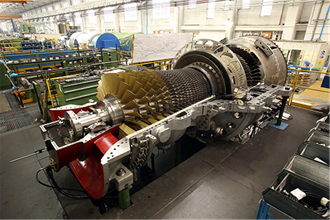

NU202EC and NJ202ECP are both cylindrical roller bearings, widely used in various mechanical equipment, especially suitable for high load and high-speed operating environments. Their design features, material selection, and application scenarios are different, but all focus on providing high load-bearing capacity and reliability.

1. NU202EC cylindrical roller bearing

Design Structure: NU202EC adopts an open design, which means there is no inner or outer ring seal, suitable for dust-free or low environmental requirements applications.

Rolling element form: The cylindrical roller design allows the bearing to withstand large radial loads, making it suitable for heavy-duty and high-speed mechanical systems.

Inner and outer ring coordination: The outer ring of NU series bearings is groove free, and the inner ring can expand freely, allowing the bearing to move radially within a certain range, suitable for environments with large temperature fluctuations.

Application areas: Widely used in heavy-duty mechanical equipment such as electric motors, reducers, gearboxes, etc.

Main features:

High load-bearing capacity, suitable for heavy-duty applications.

Can run at higher speeds.

Adapt to temperature changes and have good thermal expansion adaptability.

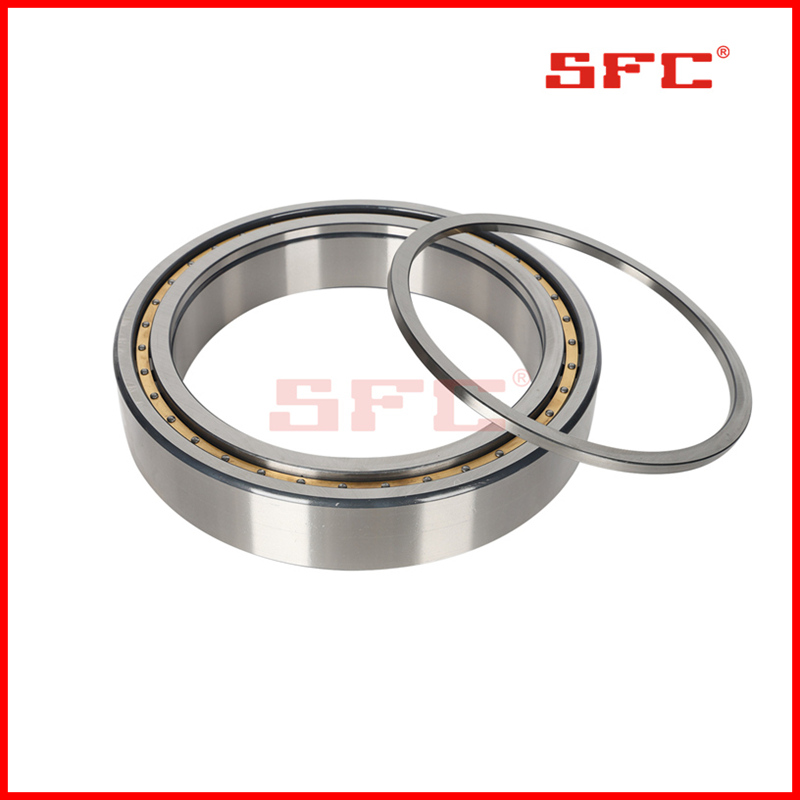

2. NJ202ECP cylindrical roller bearing

NJ202ECP adopts a design with a retaining ring, which enables it to withstand more axial loads during operation. This structure is suitable for situations where it can withstand bidirectional axial forces.

Rolling element form: cylindrical roller, with excellent radial load capacity.

Inner and outer rings and cage:

NJ202ECP adopts a cage structure to maintain the gap between the rollers and the raceway, thereby reducing friction and improving the stability of the bearing.

Application areas: Suitable for drive shafts, electric motors, transmission devices, metallurgical equipment, and other high load machinery.

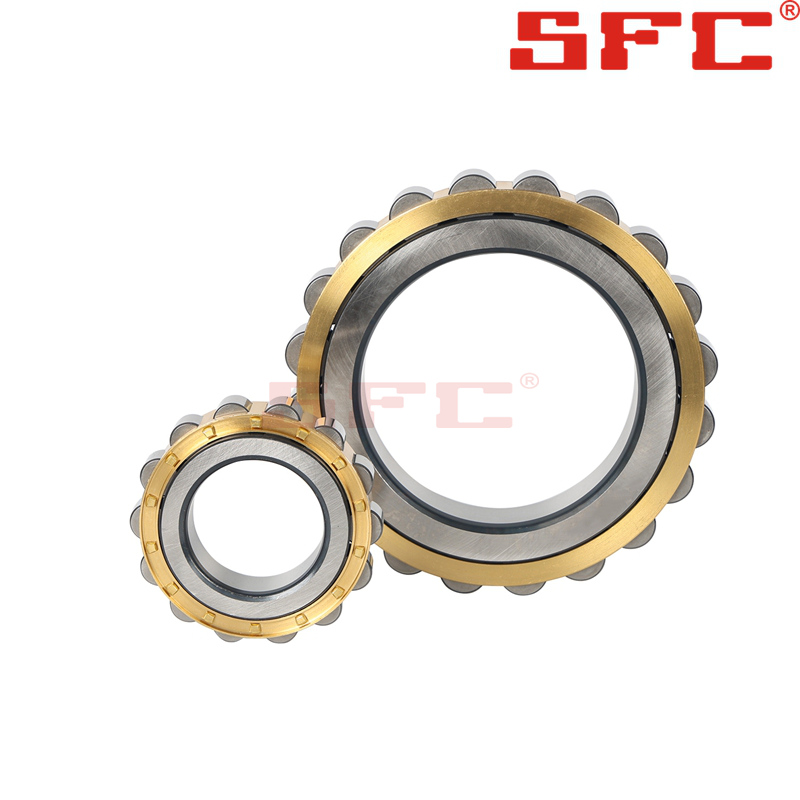

Main features:

It has good axial load-bearing capacity and is suitable for working environments that can withstand both radial and axial loads simultaneously.

More suitable for work under high-speed operating conditions.

Designing structures can effectively reduce friction and extend service life.

Comparative analysis: NU202EC and NJ202ECP

| Features | NU202EC | NJ202ECP |

| Design type | Open (without retaining ring) | with retaining ring design (able to withstand axial loads) |

| Main capacity | mainly to withstand radial loads | withstand both radial loads and bidirectional axial loads |

| Application | heavy loads, high-speed operation, and relatively clean environments | high loads, requiring the ability to withstand both radial and axial loads simultaneously |

| Temperature adaptability | Good thermal expansion adaptability, suitable for large temperature fluctuations | Excellent friction performance and efficient rotational performance |

| Typical applications | Electric motors, reducers, industrial machinery | transmission systems, metallurgical machinery, gear transmission systems |

APPLICATION

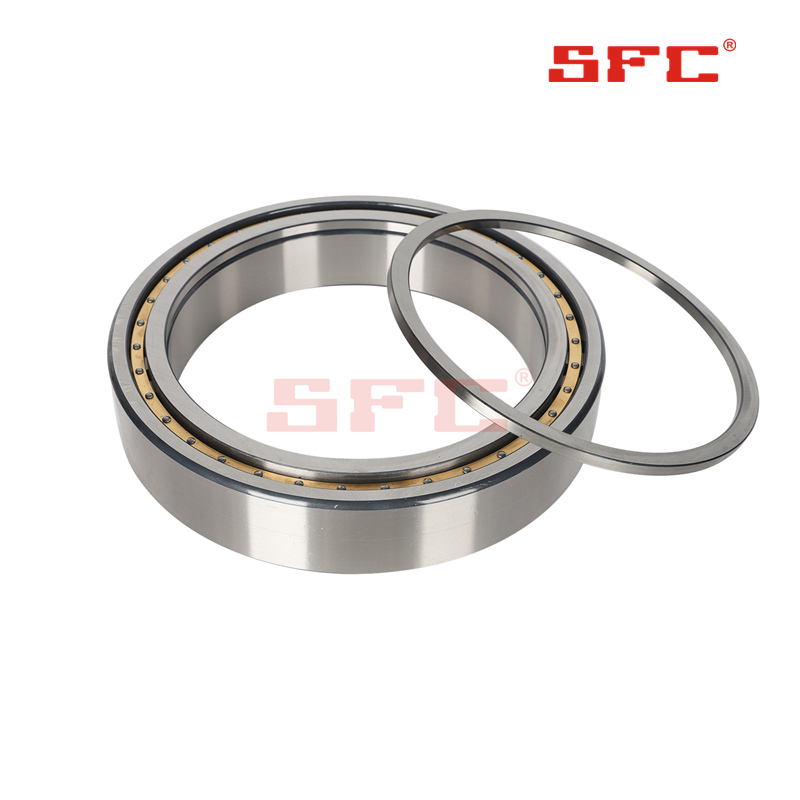

NU202EC is suitable for high-speed operating machinery in most heavy-duty and general temperature environments, especially in situations where free expansion and bearing large radial loads are required.

NJ202ECP is suitable for environments that require simultaneous radial and axial loads, especially in high-precision and high load mechanical equipment, providing better stability and long lifespan.

The choice of bearing depends on your specific needs, including factors such as load type, operating environment, and temperature changes.

Contact Us

More about Hot Sale Spherical Roller Bearing NU202EC NJ202ECP details..Looking Forward to cooperate with you,kindly contact us,give you the best quotation.

| Features | NU202EC | NJ202ECP |

| Design type | Open (without retaining ring) | with retaining ring design (able to withstand axial loads) |

| Main capacity | mainly to withstand radial loads | withstand both radial loads and bidirectional axial loads |

| Application | heavy loads, high-speed operation, and relatively clean environments | high loads, requiring the ability to withstand both radial and axial loads simultaneously |

| Temperature adaptability | Good thermal expansion adaptability, suitable for large temperature fluctuations | Excellent friction performance and efficient rotational performance |

| Typical applications | Electric motors, reducers, industrial machinery | transmission systems, metallurgical machinery, gear transmission systems |